Table of Contents

Toggle

Freshly cut timber from trees typically holds excessive moisture, making it impractical and dimensionally unstable for regular use. Seasoning, the process of reducing timber’s moisture content, serves to mitigate potential fermentation and render it suitable for various applications. Essentially, seasoning involves drying the wood to a moisture level approximately akin to the ambient humidity of its intended permanent location. It’s essential to avoid rapid seasoning right after bark removal as it can result in case hardening, which toughens the wood and increases resistance to preservative penetration.

The objectives of seasoning wood are multifaceted:

- Minimize shrinkage and warping upon incorporation into structures.

- Enhance strength, durability, and workability.

- Mitigate tendencies to split and decay.

- Prepare it for painting applications.

- Reduce overall weight.

Methods of seasoning

Timber can undergo seasoning through natural or artificial methods.

Natural or Air Seasoning

Natural seasoning involves sawing the log into planks of suitable sizes, stacking them in alternating layers, and placing them under a covered shed in a crosswise manner to allow for proper air circulation . The duration required for drying varies based on the wood type and plank sizes. However, natural air seasoning progresses at a relatively slow rate. Typically, this method reduces the wood’s moisture content to around 12–15%. It’s commonly employed in drying ties and large structural timbers due to its extensive use

Artificial Seasoning

The prevalent methods of artificial seasoning are as follows:

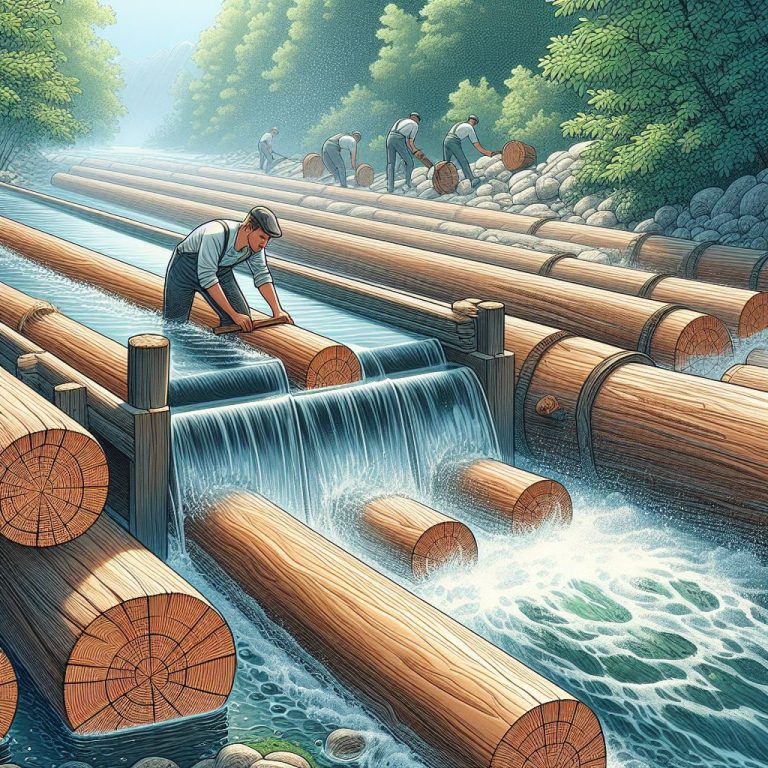

Water Seasoning

In this method, logs of wood are fully submerged in a flowing stream of water, positioning their larger ends upstream. This process facilitates the leaching out of sap, sugar, and gum from the wood, which are then replaced by water. Subsequently, the logs are removed from the water and left exposed to the air for drying. While this technique is rapid, it comes with drawbacks: the wood’s elasticity and strength tend to decrease as a result of this treatment.”

Boiling

Boiling wood in water or subjecting it to steam spray is an expedited but costly method of seasoning.

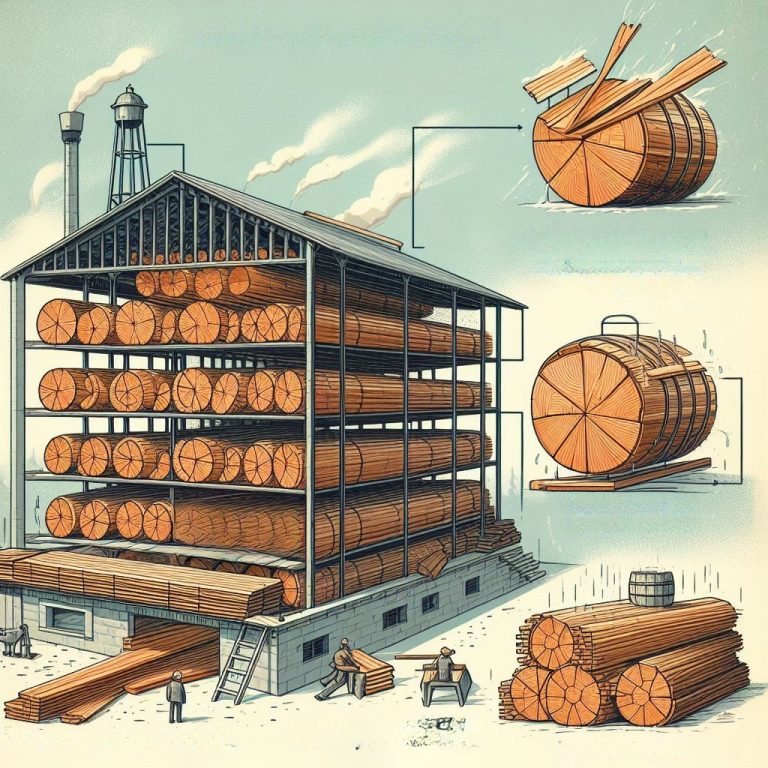

Kiln seasoning

This method is employed for rapid large-scale seasoning of timber to achieve specific moisture content levels. It involves arranging the scantlings in a manner that allows for the circulation of heated air containing some moisture or superheated steam. The circulating air absorbs the necessary moisture from the wood, effectively seasoning it. There are two primary types of kilns in use: the progressive and the compartment kilns.

For successful kiln-seasoning, it’s crucial to raise the timber to a temperature that it can endure without damage before initiating the drying process. Otherwise, moisture in the hot outer fibers of the wood may move towards the cooler interior. Kiln drying typically results in a minimal loss in timber strength, usually less than 10%. Additionally, this method ensures more thorough and uniform drying, thereby reducing the wood’s hygroscopic nature.

Chemical or Salt Seasoning

Chemical or salt seasoning involves using an aqueous solution of specific chemicals that possess lower vapor pressures than pure water. When the outer layers of timber are treated with such chemicals, they create a reduction in vapor pressure, establishing a gradient. This gradient sets up a scenario where the interior, devoid of these salts, maintains its original vapor pressure, facilitating a more rapid drying compared to untreated wood.

This process effectively flattens the moisture gradient curves, lessening their slope and subsequently reducing the internal stresses that typically arise during drying. As these stresses often lead to defects like checks, chemically treated timber tends to exhibit fewer of these imperfections. Commonly used substances include salt or urea, with the latter being preferred due to common salt’s tendency to cause corrosive reactions.

Electric Seasoning

In electric seasoning, logs are positioned to ensure both ends make contact with electrodes. When an electric current passes through the setup, wood, being a poor conductor, impedes the flow of current. This resistance generates heat, facilitating the drying process. However, a potential drawback is that this method can sometimes lead to splitting of the wood.

Mc. Neill’s Process has no adverse effects; it is the best method although most expensive. The timber is stacked in a chamber with free air space (l/3rd of its capacity) and containing products of combustion of fuels in the fire place. The time required for complete seasoning is 15 to 60 days.