Table of Contents

ToggleFactors Affecting Workability of concrete

Workability is a key property of fresh concrete, indicating how easily it can be mixed, placed, compacted, and finished while maintaining its homogeneity. A workable concrete mixture overcomes internal friction between particles and the frictional resistance from formwork or reinforcement with minimal compacting effort. Several factors contribute to enhancing the lubricating effect of concrete, thereby reducing internal friction and improving its ease of compaction. These factors include water content, mix proportions, aggregate size, shape, surface texture, grading, and the use of admixtures.

Workability encompasses two primary aspects: consistency and cohesiveness, each influenced by different characteristics of the concrete mix. While certain factors may enhance one aspect, they might adversely affect the other. Key contributors to workability include the properties of constituent materials, mix proportions, and environmental conditions. Proper consideration of these factors ensures that the concrete achieves the desired balance between fluidity and stability, making it suitable for specific construction applications.

The following are the key factors affecting workability of concrete:

a) Water Content

Water content significantly influences the workability of concrete. Higher water content increases the fluidity of concrete, making it easier to mix, place, and compact. This is because water acts as a lubricant by creating a film around cement and aggregate particles, reducing internal friction. However, excessive water can lead to issues like segregation, bleeding, and a reduction in strength.

In practice, site supervisors sometimes increase water content to enhance workability quickly, but this approach should be a last resort. For controlled concrete, arbitrarily increasing water is not advisable. If additional water is necessary, the water-to-cement ratio must be maintained by adding more cement to prevent a loss of strength.

The workability of lean concrete (with a high aggregate-to-cement ratio) is often limited due to insufficient cement paste to lubricate aggregate particles, restricting mobility. In contrast, rich concrete (with a low aggregate-to-cement ratio) has ample paste, resulting in better cohesiveness and improved workability. Properly balancing water content is essential to achieve the desired workability without compromising the structural integrity of the concrete.

b) Cement Content

Cement content significantly impacts the workability of concrete through its role in water retention and lubrication. At a given water-cement (w/c) ratio, higher cement content increases the total water available in the mix, enhancing fluidity and improving consistency. Additionally, cement paste acts as a lubricant, coating and filling aggregate particles to facilitate smoother placement and compaction.

In normal concrete, insufficient cement content often results in a harsh, inconsistent mixture with poor finishability. Conversely, high cement content provides better lubrication, enhancing both consistency and cohesiveness. This effect is more pronounced at lower w/c ratios, where the increase in cement content improves the overall workability.

The fineness of cement particles also affects workability. While finer cement may reduce fluidity at a given w/c ratio, it enhances cohesiveness, creating a well-bonded mixture. However, concrete with excessively high cement content or very fine cement particles may become sticky, which could pose challenges during handling and finishing. Balancing cement content is essential to achieve the desired balance of workability, cohesiveness, and finishability.

(c) Aggregate Characteristics

Aggregate properties significantly influence the workability of concrete through their impact on surface coating requirements, friction, and mobility during mixing, placing, and compaction. The key factors affecting workability include aggregate size, aggregate-to-cement ratio, fine-to-coarse aggregate ratio, and aggregate shape and texture.

Aggregate Size: Larger aggregates have a smaller surface area relative to their volume, requiring less cement paste for coating. This increases the amount of paste available for lubrication, improving fluidity and consistency. Conversely, smaller or finer aggregates demand more paste, potentially making the mixture less workable.

Aggregate-to-Cement Ratio: A higher ratio implies more aggregates and less cement paste, reducing lubrication and decreasing consistency. Maintaining the right balance is crucial for achieving desirable workability.

Fine-to-Coarse Aggregate Ratio: Increasing the fine aggregate proportion raises the total surface area, leading to higher paste demand for coating. While this may reduce consistency, it enhances cohesiveness, which can be advantageous for specific applications requiring stability.

Shape and Texture: The shape and surface texture of aggregate particles also affect workability. Spherical, smooth aggregates reduce friction and require less paste, resulting in more workable concrete. In contrast, angular, rough, or irregular aggregates demand more paste and increase internal friction, leading to harsher mixes.

Optimizing aggregate characteristics ensures the concrete achieves the desired balance of fluidity, cohesiveness, and ease of handling.

(d) Use of Admixtures

Admixtures, both chemical and mineral, play a crucial role in enhancing the workability of concrete by influencing its fluidity, cohesiveness, and overall consistency.

1. Chemical Admixtures:

- Air-Entraining Agents: These increase the paste volume and improve consistency by introducing air bubbles, which act as lubricants. They also enhance cohesiveness by reducing segregation and bleeding, especially in harsh, low-cement mixtures like mass concrete.

- Water-Reducing Admixtures (Plasticizers and Superplasticizers): These improve fluidity by dispersing cement particles and releasing entrapped water. For optimal effectiveness, the initial slump of the reference mix should be around 2 to 3 cm. This ensures maximum workability improvement at a minimal dosage, maintaining cost-effectiveness.

2. Mineral Admixtures:

- Fly Ash: As a partial cement replacement, fly ash improves consistency due to its spherical shape and smooth, glassy surface.

- Silica Fume: While silica fume increases cohesiveness, it can reduce fluidity due to its high surface area, which demands more water for lubrication.

Admixtures like air-entraining agents also reduce internal friction, enabling particles to slide past each other more easily. Additionally, fine pozzolanic materials, despite increasing surface area, enhance lubricating effects, resulting in better workability. The thoughtful selection and dosage of admixtures can dramatically improve the handling and performance of concrete mixtures.

(e) Temperature and Time

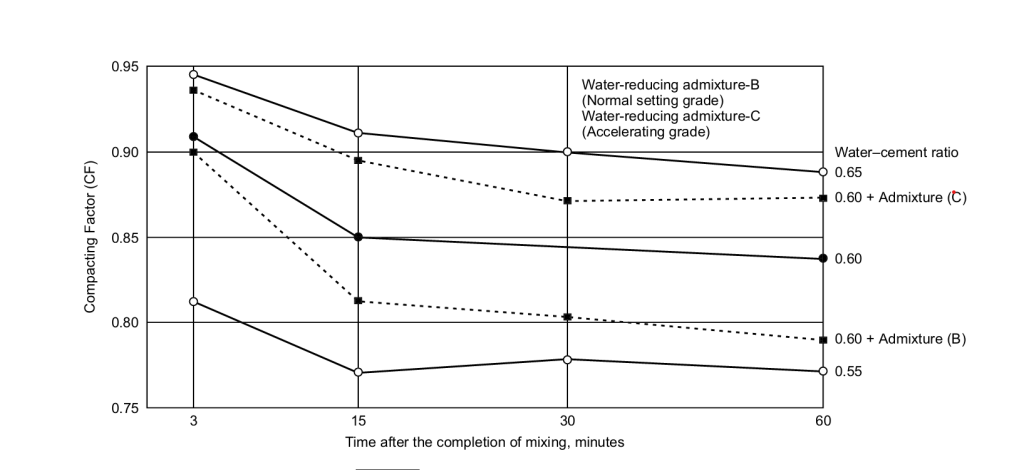

The workability of freshly mixed concrete decreases over time due to various factors, including water evaporation (accelerated by sun or wind exposure), water absorption by aggregates, and its consumption during the hydration process. This phenomenon, known as slump loss, is influenced by:

- Mix Richness: Richer mixes typically experience slower slump loss.

- Cement Type: Different types of cement have varying hydration rates, which affect workability over time.

- Temperature: Higher temperatures accelerate the hydration process and water evaporation, resulting in reduced workability and faster slump loss.

- Initial Workability: Mixtures with low initial workability are more sensitive to time-induced stiffening.

To address challenges posed by high temperatures or unusual site conditions, conducting on-site workability tests is recommended. Proper planning, including the use of water-retaining measures or admixtures, can help maintain desired workability levels under such conditions.

(f) Mix Proportions

The aggregate-to-cement ratio significantly impacts the workability of concrete:

- Lean Concrete: A higher aggregate-to-cement ratio results in leaner concrete, where less cement paste is available for lubrication. This limits the mobility of aggregates, reducing workability.

- Rich Concrete: A lower aggregate-to-cement ratio increases the availability of cement paste, making the mix cohesive and smooth, thus enhancing workability.

Optimizing mix proportions ensures the right balance between cohesiveness and fluidity, crucial for achieving desired workability.

(g) Grading of Aggregates

The grading of aggregates plays a critical role in influencing the workability of concrete. Well-graded aggregates, which have the least amount of voids for a given volume, require less paste for lubrication. This results in:

- Reduced Void Spaces: With fewer voids, more paste is available to lubricate the particles, improving workability.

- Enhanced Cohesion: The excess paste makes the mixture cohesive and “fatty,” helping prevent segregation of particles.

- Ease of Compaction: The better the grading, the less compacting effort is required, as the aggregate particles can slide past one another more easily.

In short, a well-graded aggregate mix results in a more workable, cohesive, and stable concrete mixture.

Frequently Asked Questions

The seven main factors affecting concrete workability are:

- Water content

- Cement content

- Aggregate characteristics

- Use of admixtures

- Temperature and time

- Mix proportions

- Grading of aggregates

The most significant factors are water content and aggregate characteristics. Water content directly influences fluidity, while aggregate properties (size, shape, and texture) affect the concrete’s internal friction and mobility. These factors have the most immediate and noticeable impact on workability.

All concrete components and environmental conditions affect workability to some degree. However, factors like the color of aggregates, the brand of cement, and the time of day (apart from temperature effects) do not significantly impact concrete workability.

Here’s how each factor affects concrete workability:

- Water Content: Acts as a lubricant, increasing fluidity

- Cement Content: Provides paste for coating and lubrication

- Aggregate Characteristics: Influences internal friction and mobility

- Admixtures: Modify concrete properties to enhance workability

- Temperature: Affects hydration rate and water evaporation

- Mix Proportions: Determine paste availability for lubrication

- Aggregate Grading: Affects void content and paste requirements

Aggregate characteristics influence workability through:

- Size: Larger aggregates require less paste for coating, improving fluidity

- Shape: Round, smooth aggregates enhance workability compared to angular ones

- Surface texture: Smooth surfaces reduce water demand and improve workability

- Grading: Well-graded aggregates require less paste and improve overall workability

Key admixtures that improve workability include:

- Water-reducing admixtures (plasticizers)

- Superplasticizers

- Air-entraining agents

- Mineral admixtures like fly ash These additives can enhance fluidity and maintain workability without increasing water content.