Table of Contents

ToggleIntroduction

Aggregates are fundamental components of concrete, contributing significantly to its strength, durability, and overall performance. As the primary fillers in concrete, aggregates occupy approximately 60–80% of its volume, influencing both its mechanical properties and cost-effectiveness. Understanding the classification of aggregates is essential for selecting the right type for specific construction requirements.

Aggregates are classified based on three key criteria: size, source, and unit weight. Each classification provides insights into their physical and functional properties, making them suitable for various applications. For example, size-based categories distinguish between coarse aggregates used in structural members and fine aggregates like sand, which ensure proper compaction and smooth finishes. Aggregates can also be grouped by their source, ranging from naturally occurring materials like sand and gravel to manufactured aggregates derived from industrial by-products, promoting sustainability. Furthermore, unit weight-based classification highlights their role in producing concrete with varying densities, from lightweight panels to heavy-duty radiation shields.

This article delves into these classifications, providing a comprehensive overview of the characteristics, examples, and applications of different types of aggregates. By understanding these distinctions, engineers and builders can make informed choices to meet the demands of modern construction efficiently and sustainably.

Classification of Aggregates Based on Size

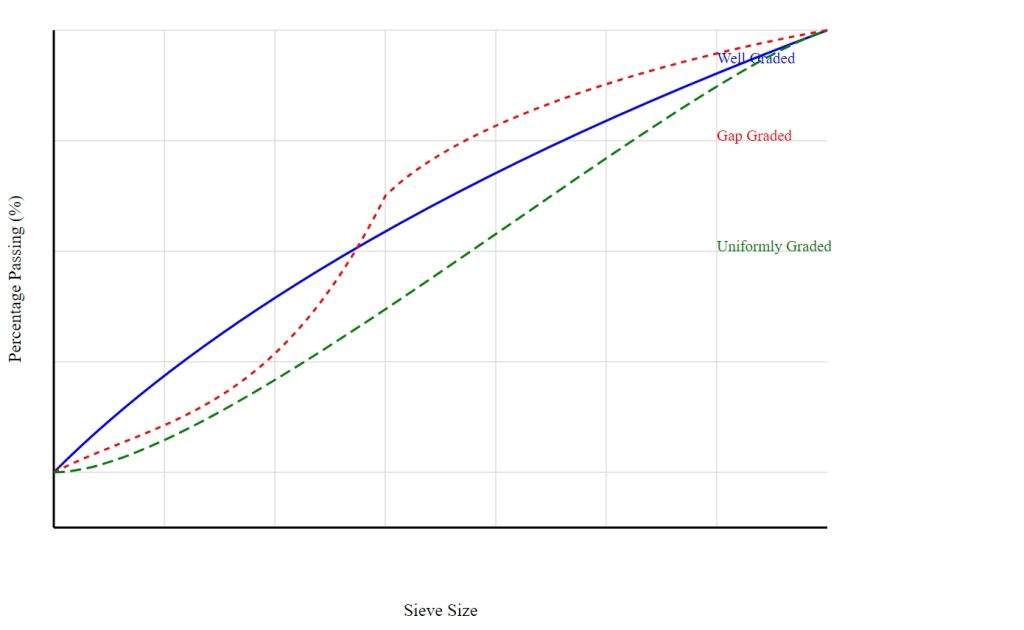

The size of aggregates plays a critical role in determining the properties of concrete in both fresh and hardened states. Aggregate sizes can range from a few centimeters down to microscopic particles. Regardless of their size, aggregates must be graded such that different particle size fractions are appropriately proportioned in the mix to achieve optimal performance. This distribution of particle sizes is referred to as the grading of the aggregate. Aggregates are classified into four categories based on size: fine aggregate, coarse aggregate, all-in-aggregate and Single-Size Aggregate

i. Fine Aggregate

Definition:

Fine aggregate consists of particles that predominantly pass through a 4.75 mm IS sieve while retaining only as much coarser material as specified by standards.Particle Size Range:

- Lower limit: Approximately 0.07 mm.

- Particles smaller than 0.06 mm are classified as silt, while those under 0.002 mm are referred to as clay.

- Deposits with sand, silt, and clay in similar proportions are termed loam.

Types of Fine Aggregate:

- Natural Sand: Derived from the natural disintegration of rock or deposition by streams and glacial processes.

- Crushed Stone Sand: Produced by crushing hard stones.

- Crushed Gravel Sand: Created by crushing natural gravel.

Grading Zones:

According to IS: 383–1970, fine aggregate is divided into four grading zones, which progressively become finer from Zone I to Zone IV.Sub-Classifications Based on Size:

- Coarse sand.

- Medium sand.

- Fine sand.

ii. Coarse Aggregates

Definition:

Coarse aggregate consists of particles predominantly retained on a 4.75 mm IS sieve, containing only as much fine material as permitted by specifications.Types of Coarse Aggregate:

- Crushed Gravel or Stone: Obtained by crushing hard stone or gravel.

- Uncrushed Gravel or Stone: Formed by the natural disintegration of rock.

- Partially Crushed Gravel or Stone: A blend of crushed and uncrushed materials.

Nominal Size:

Coarse aggregates are typically described by their nominal size, such as 40 mm, 20 mm, 16 mm, and 12.5 mm. For instance, a 20 mm nominal size aggregate means most particles pass through a 20 mm IS sieve, with the majority retained on a 10 mm IS sieve.Properties Influenced by Parent Rock:

Coarse aggregate inherits many properties from its parent rock, such as:- Chemical and mineral composition.

- Specific gravity, strength, and stability.

- Pore structure and hardness.

Additional properties like particle shape, surface texture, and absorption influence the performance of concrete but are not inherent to the parent rock.

iii. All-in Aggregate

Definition:

This refers to naturally available aggregates comprising a mix of fine and coarse fractions.Applications:

Adjustments are often necessary to supplement grading with deficient size fractions. While convenient, all-in aggregates are not typically used for high-quality concrete, as their properties might not meet the stringent requirements of structural applications.Nominal Size:

Similar to coarse aggregates, all-in aggregates are also described by their nominal size.

iv. Single-Size Aggregate

Definition:

Single-size aggregates consist of particles falling within a narrow size range.Examples:

- A 20 mm single-size aggregate refers to aggregates where most particles pass through a 20 mm IS sieve, with the majority retained on a 10 mm IS sieve.

Applications:

These aggregates are used for specific construction needs, such as producing uniform textures or achieving precise grading requirements.

Classification of Aggregates Based on Source

Aggregates can also be classified based on their origin, broadly categorized into natural aggregates and manufactured (synthetic) aggregates.

1. Natural Aggregates

These are aggregates sourced directly from natural deposits such as riverbeds, quarries, or lakes, without altering their composition during production.

- Examples: Sand, gravel, and crushed stone.

- Characteristics:

- Naturally occurring and widely available in many regions.

- Smooth texture (especially in river sand) improves the workability of concrete.

- Environmentally friendly but subject to depletion, leading to a growing reliance on alternatives.

Natural aggregates are commonly used in construction due to their compatibility with cement and ease of availability. However, the over-extraction of these resources has raised concerns about environmental sustainability.

2. Manufactured (Synthetic) Aggregates

Manufactured aggregates are artificially created materials derived from industrial processes or by-products. These aggregates are engineered to meet specific construction needs.

Examples:

- Blast furnace slag: A by-product of steel production, often used as a durable and cost-effective aggregate.

- Lightweight aggregates: Materials like expanded clay, shale, or fly ash, used to produce lightweight concrete.

- Artificial sand: Produced by crushing stones or other materials, providing a sustainable alternative to natural sand.

Characteristics:

- Engineered properties for enhanced performance (e.g., lightweight or high durability).

- Utilizes industrial by-products, contributing to waste reduction and sustainable practices.

- Widely adopted in regions facing a scarcity of natural aggregates.

The production and use of artificial aggregates, particularly artificial sand, have surged globally due to increased demand in construction. This shift supports the construction industry’s transition toward sustainability while addressing the depletion of natural resources.

Classification of Aggregate Based on Unit Weight

Aggregates can also be categorized by their unit weight, which determines the density and specific applications of the concrete produced. The four primary classifications are:

1. Ultra-Lightweight Aggregate

- Unit Weight: Less than 500 kg/m³.

- Examples: Expanded perlite, foam plastic.

- Concrete Properties:

- Bulk density ranges between 800–1100 kg/m³, depending on the aggregate’s volume fraction.

- Used exclusively for non-structural applications such as partition walls, ceilings, or thermal insulation panels.

- Advantages: Lightweight and excellent thermal and sound insulation properties.

- Limitation: Low strength, unsuitable for load-bearing purposes.

2. Lightweight Aggregate

Unit Weight: Between 500–1120 kg/m³.

Examples:

- Cinder

- Blast-furnace slag

- Volcanic pumice

- Expanded clay and fly ash

Concrete Properties:

- Bulk density ranges from 1200–1800 kg/m³.

- Applications:

- Structural members (e.g., lightweight concrete floors or precast panels) when using denser aggregates.

- Non-structural components when using aggregates like volcanic pumice or expanded materials.

Lightweight aggregate concrete is valued for its reduced self-weight, making it suitable for multi-story buildings and bridges while reducing construction loads.

3. Normal-Weight Aggregate

Unit Weight: Greater than 2100 kg/m³.

Examples:

- Iron ore

- Crushed steel pieces

- Magnesite and limonite

Concrete Properties:

- Bulk density exceeds 3200 kg/m³, and can reach up to 4000 kg/m³.

- Applications:

- Specialized use in radiation shielding for nuclear power plants, hospitals, and research laboratories.

- Soundproofing and vibration isolation in sensitive environments like recording studios or industrial facilities.

Heavy-weight aggregates create dense concrete with unique protective properties, tailored for highly specific construction needs.

4. Heavy-Weight Aggregate

Unit Weight: Greater than 2100 kg/m³.

Examples:

- Iron ore

- Crushed steel pieces

- Magnesite and limonite

Concrete Properties:

- Bulk density exceeds 3200 kg/m³, and can reach up to 4000 kg/m³.

- Applications:

- Specialized use in radiation shielding for nuclear power plants, hospitals, and research laboratories.

- Soundproofing and vibration isolation in sensitive environments like recording studios or industrial facilities.

Heavy-weight aggregates create dense concrete with unique protective properties, tailored for highly specific construction needs.

Classification of Aggregates Based on Shape

The shape of aggregates plays a crucial role in influencing the properties of fresh concrete, particularly its workability, cohesion, and bond strength. While the shape has a lesser effect on the properties of hardened concrete, it is still critical for achieving desired structural performance. Aggregates are typically classified into four categories based on particle shape: rounded, irregular or partly rounded, angular, and flaky or elongated.

1. Rounded Aggregates

Characteristics:

- Derived from natural sources like river or seashore gravel.

- Contain minimum voids, typically 32–33%, resulting in a lower surface area-to-volume ratio.

- Require less cement paste for the same workability, reducing material costs.

Advantages:

- Excellent for producing economical and workable concrete.

Limitations:

- Poor interlocking between particles, leading to weak bond development.

- Unsuitable for high-strength concrete and load-bearing pavements due to reduced structural integrity.

2. Irregular Aggregates

Characteristics:

- Partly rounded particles sourced from materials like pit sand and gravel.

- Contain voids in the range of 35–38%, requiring more cement paste for adequate workability.

Advantages:

- Slightly better interlocking than rounded aggregates.

Limitations:

- Still inadequate for high-strength or high-performance concrete due to limited bonding capabilities.

3. Angular Aggregates

Characteristics:

- Sharp-edged, angular, and rough particles, typically from crushed rocks.

- Contain the highest void percentage (38–40%) among all shapes.

Advantages:

- Excellent interlocking properties, resulting in strong bonding with cement paste.

- Suitable for high-strength concrete, pavements, and tension-resisting structural elements.

Limitations:

- Require more cement paste to achieve workable concrete due to higher void content.

4. Flaky and Elongated Aggregates

Characteristics:

- Flaky aggregate: Particles where the least dimension (thickness) is less than three-fifths of the mean dimension.

- Elongated aggregate: Particles where the greatest dimension (length) exceeds nine-fifths of the mean dimension.

Effects on Concrete:

- Reduced workability and durability, as flaky and elongated particles tend to orient in one plane, creating voids beneath.

- Adverse effects on the concrete’s compressive and flexural strength.

Recommendations:

- Limit flaky and elongated particles to 10–15% of the total aggregate volume, particularly for crushed fine aggregates.

- Use proper tests like flakiness index and elongation index (as per IS: 2386-1963) to control particle shapes.